Many beginners assume the only way to increase profit is to import cheaper products. In reality, cutting quality often leads to refunds, customer complaints, and lost trust. The smarter approach is reducing unnecessary costs around the product while maintaining quality. This guide explains how Zambian importers can lower importing costs without damaging product standards.

Step 1: Understand Where Your Costs Really Come From

Before reducing costs, you must know what you are paying for.

Common cost areas:

- Product cost

- Shipping (air or sea)

- Customs & clearing

- Packaging

- Local transport

Many importers focus only on product price, while shipping and inefficiencies quietly consume profits.

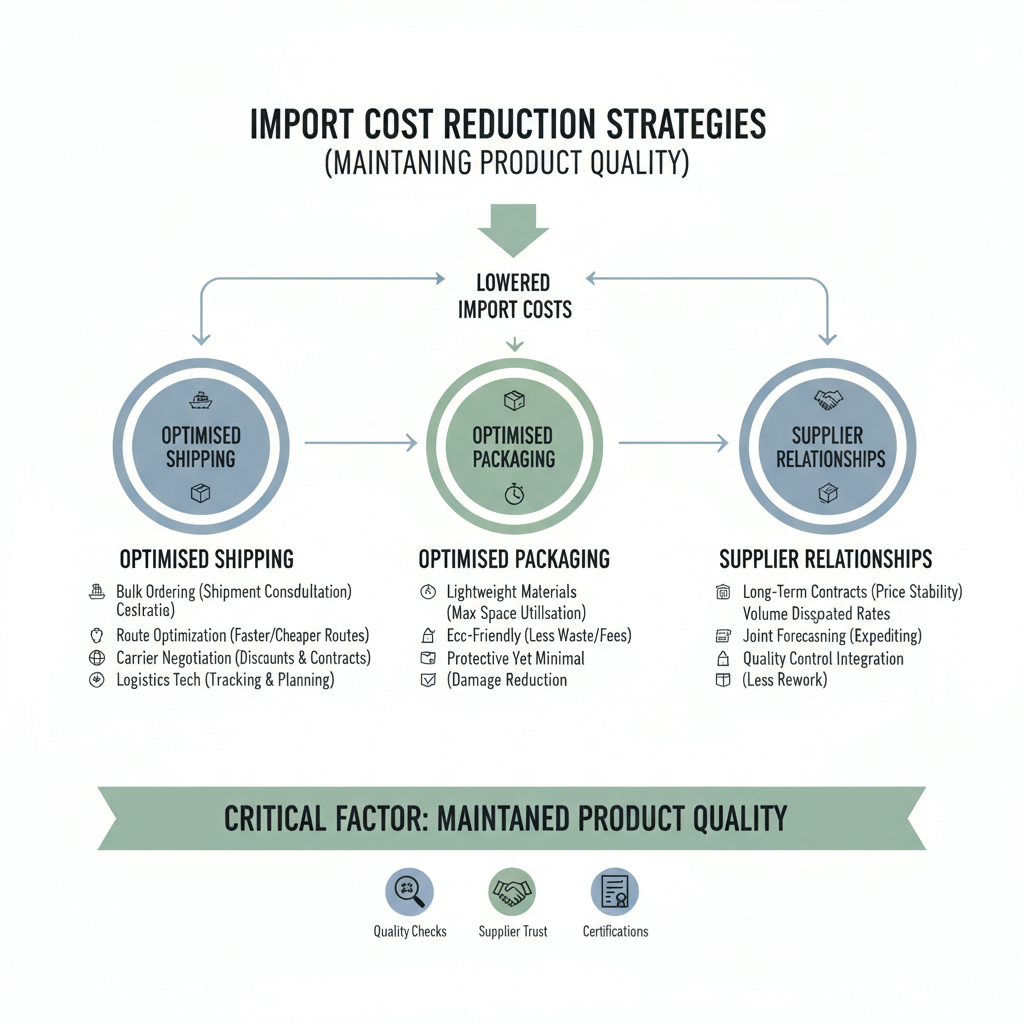

Step 2: Optimise Shipping Decisions

Shipping is often the biggest variable cost.

Ways to reduce shipping costs:

- Consolidate shipments instead of frequent small orders

- Choose slower shipping when stock timing allows

- Avoid shipping half-empty cartons

Better planning reduces urgency, which reduces cost.

Step 3: Negotiate Packaging, Not Product Quality

Suppliers may not lower product price, but they often adjust packaging.

Smart adjustments:

- Reduce unnecessary inner packaging

- Optimise carton size to reduce volume

- Keep protective packaging for fragile items

This lowers shipping cost without affecting the product itself.

Step 4: Build Supplier Relationships

Long-term suppliers offer better terms.

Benefits include:

- Better pricing over time

- Priority production

- More flexible minimum order quantities

Suppliers are more willing to help repeat buyers than first-time customers.

Step 5: Avoid False Cost-Cutting

Some “cost savings” create bigger losses.

Avoid:

- Skipping samples

- Ignoring quality checks

- Choosing untested suppliers

These shortcuts often lead to unsellable stock.